This work was done over several days:

- Researched horizontal stabilizer mounting: plans, video and blogs.

- Did some initial positioning of stabilizer and found that the right aft flange of the hs-00005 rib was interfering with the vertical mounting bar. To fix this I removed the rivets holding the flange to the rear spar and carefully trimmed the flange. I wedged a sacrificial piece of very thin aluminum between the rib and spar to protect the spar.

- Made the forward 1/8" spacers for the horizontal stab

- Triple checked and marked center lines on the aft fuselage deck where the stab mounts.

- Also marked the longeron outline to make sure I could drill with good edge distance

- Clamped stab in place and checked alignment with wings and fuselage. I used the technique of drilling a hole in the tape measure and using a cleco to secure it - works great for accurate solo measurements.

- Once everything was triple checked and clamped I drilled through the stab, spacer and longeron. I bolted the left side down, rechecked measurements and drilled the right. I did have to make a spacer for the left side bolt to clear a rivet.

- I replaced the rivets in the right rib flange and cleaned every thing up.

- With the stab on saw horses I drilled the inboard mounting holes from the bottom up. I then bolted the stab back on the fuselage and drilled the holes through the fuselage structure with the angle drill using the stab as a guide.

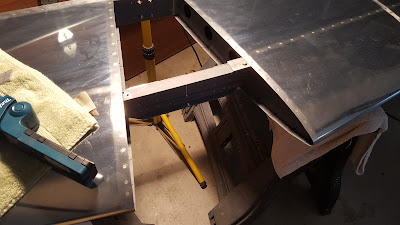

Forward stab mounting holes done:

Ready to drill the inboard holes from the bottom up:

Right bolt hole done:

After trimming rib flange:

Starting to check positioning and alignment:

Spacers made from 1/8" bar:

Dad came over to help me get started on the horizontal stab: