With the mottled pattern of the various fillers it was getting difficult to tell how the front of the cowling was progressing so I sprayed it with spraymax 2k primer filler. It actually looks a lot closer than I originally thought.

The inside of the lower cowl is about ready to be coated with clear epoxy and primed / painted.

Skim coating the cowling with rage to fill the innumerable pinholes and defects in the vans' cowling.

Working on filling the rough parts of the inside of the cowling for better paint adhesion / less nooks and crannies to catch oil once the plane is flying.

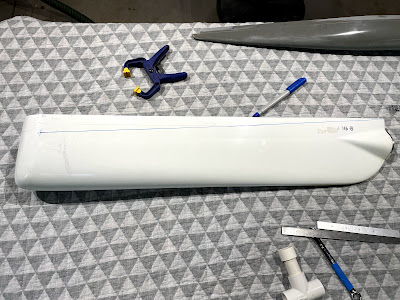

Planning on filling and priming the gear leg fairings but first I decided to reinforce the hose clamp tabs with a layer of carbon fiber followed by one layer of fiberglass:

Filling and sanding continues...

Inside of the top cowl is cleaned up and mostly ready.

The tail lynx springs turned out nice.

Paul and I updated the software on the G3X and the GTN-650:

Working on the rudder pedal to rudder cable links:

The finished links:

Checking the fit on the endless cowling...

All the empennage fairings are done and installed:

New toy: Wiha Speed e2 electric screwdriver - really a nice tool, perfect for the number six screws for all the fairings.

Finishing up the fairings:

I finished filling and priming the interface between the knockout panel and the riser fairing for the BRS parachute

Getting ready to prime the trailing edge of the rudder:

Mounting the BRS parachute knockout panel with the prescribed RTV: