- I spent about an hour getting the washers and the rod end bearing for the forward push pull tube into the forward control column. Very frustrating but worked out well. Dental floss and tape helped me finally get everything together!

- Permanently bolted the aft push pull tube and the servo to the bell crank.

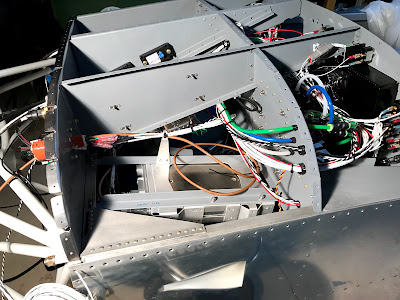

- Cleaned up angles and canister for the BRS parachute system.

- Installed the angles for the BRS canister and put the canister in place. The canister will not get bolted in until the actual parachute and rocket is installed - hopefully this summer!

- Installed the aft tunnel cover and connected the flap position sensor. I also had to do a slight reroute on the flap wiring to clear the cover.

- Installed the roll linkage for the two control sticks. This took a while to get everything lined up. This also included the tabs and springs for the roll trim system.

Stick linkage for roll - the tab is for the roll trim:

Sticks are linked up in roll:

Flap position sensor done:

Parachute canister ready for loading:

Aft push pull tube and pitch servo complete:

The washers for the control column and the forward push pull tube have been the hardest to work with so far: