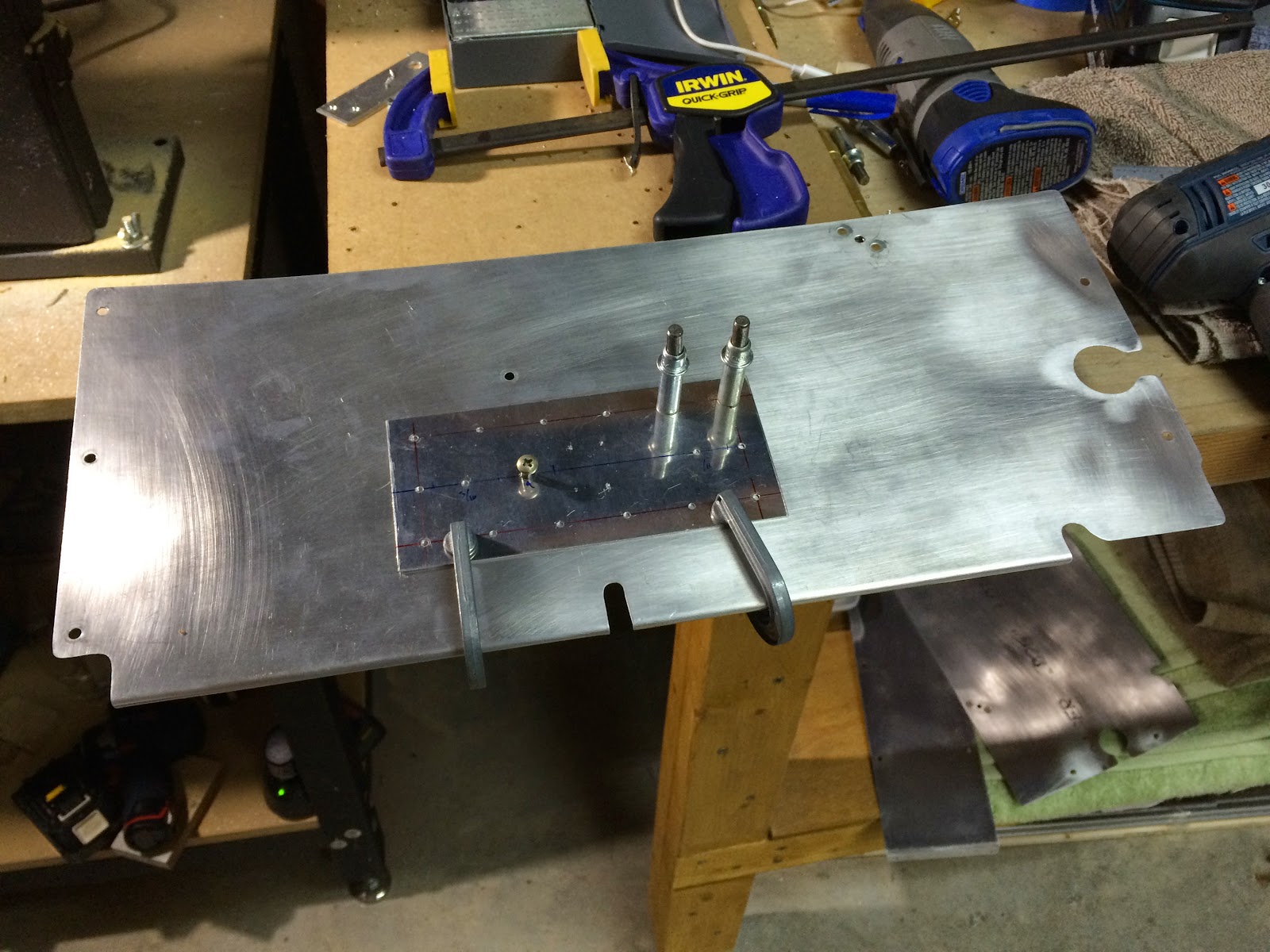

- Riveted fire extinguisher doubler to front spar cover.

- Riveted firewall fuel fitting doubler to firewall

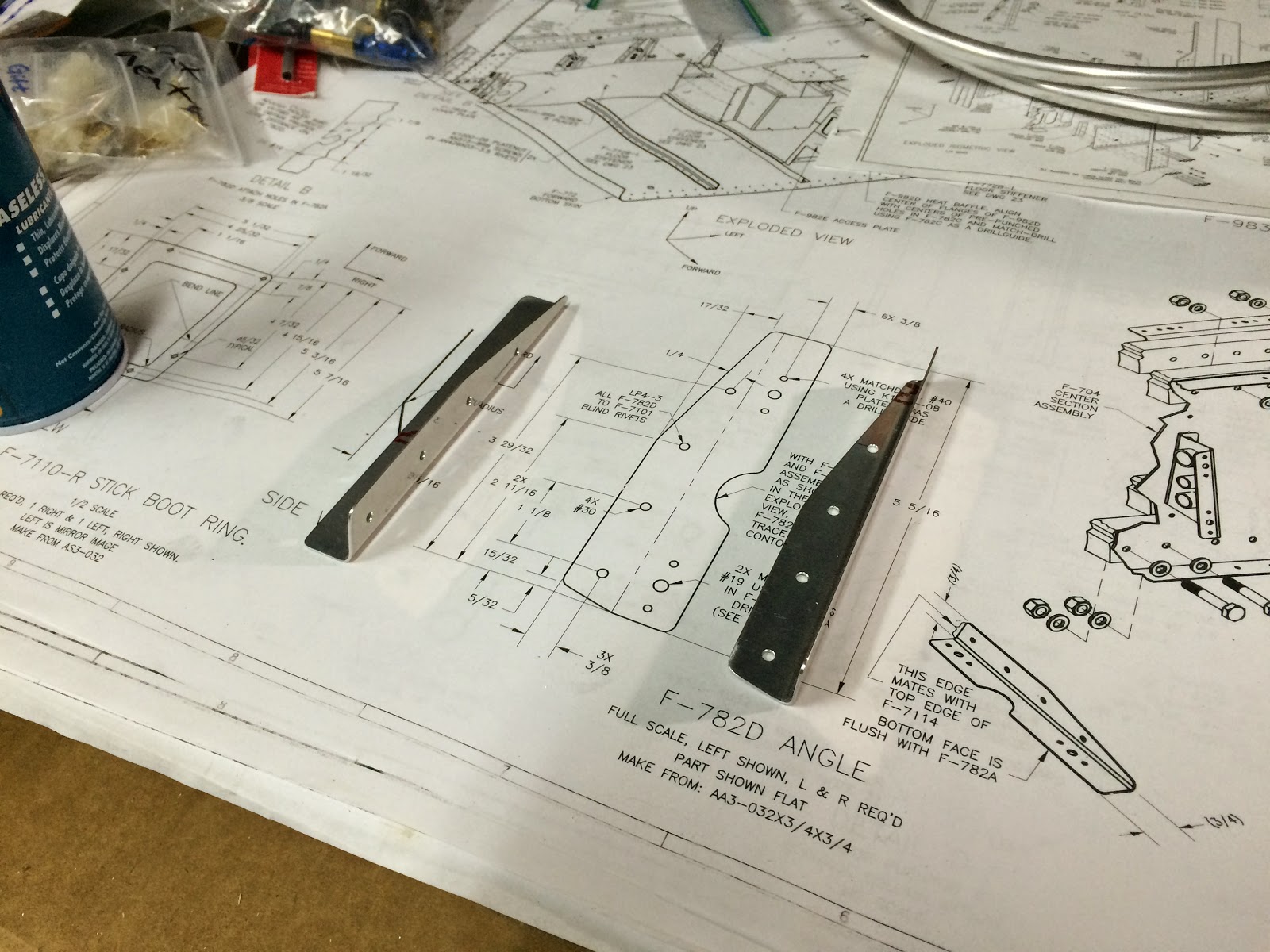

- Many hours of fuel tubing research and practice

- Made one fuel tube (later remade!)

- Modified fuel tube bender (later replaced with better 180 degree bender!)

Firewall fuel fitting and doubler:

Mocking up electric fuel pump to determine tube requirements:

Fuel pump with 1st generation 180 degree fuel line:

1st generation filter to pump line - this turned out to be too large to fit under the pump doghouse so it was later scrapped.

I went though a lot of tubing practicing but I want the fuel lines perfect.

Riveting this doubler was trickier than I expected: