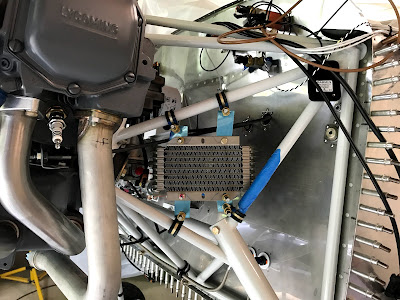

- After a fair amount of fitting I found a great location for the oil cooler that has plenty of clearance and works with my home made duct for the oil cooler valve.

- I also hooked up and tested the servo for operating the valve.

- I did the initial install on the Reiff sump heaters. This involved removing the paint from the engine sump and bonding them in place with some epoxy (similar to JB Weld). The next step is placing another bead of epoxy around the edges of the heaters and the thermostat.

- The plan for the sump heater is to have a cell phone switch in the hangar. On cold days I will just turn the heater on a couple of hours before I fly to keep the engine happy!

Oil cooler 4" air valve closed:

Open / max flow position:

Left Reiff sump heater attached. (silver object under duct tape - I will get some better pictures!) To the right of the heater is the thermostat. After the epoxy cures I will add a bead of epoxy around the edges of the heaters, wires and thermostat.

Test fitting the final oil cooler stand offs made from 1/8" aluminum bar:

Second mock up using some thin aluminum sheet scraps:

Figuring out position for oil cooler and duct:

Initial mock up: