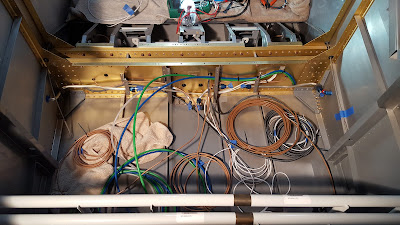

Lots of wiring and related items going on.

- Drilled 2 new wiring pass through holes in spar carry through web on left and right sides

- Drilled a few small pass through holes aft of the spar for RG-400 cable

- Pulled AOA, pitot and static pneumatic tubes through spar carry through

- Pulled a variety of other wires and cables through spar carry through

- Mounted a bunch of clickbond wire tie holders on vertical surfaces

- Mounted a bunch of wire tie holders secured with E6000 on horizontal surfaces

- Crimped on BNC connectors for the comm radio and transponder antennae

- Broke in the heat shrink wiring label printer

- Mounted the fire extinguisher bracket

- Bonded on terminal strip for Aeroled nav / strobes

Terminal strip block secured with E6000 (for Aeroled lights) and transponder RG-400 on right:

Getting more organized (clear plastic pieces are clickbond pieces being bonded):

Mounted fire extinguisher bracket on left carry through cover:

First use of the dymo heat shrink wiring label printer:

Crimping BNC connector witht the help of Stein's video:

Pitot, aoa, static pneumatic lines pulled and some misc cables:

Spar carry through web before start of wire pulling:

Close up of 2 new wiring pass through holes on left side: