In working on fitting the fuselage gussets I found that there was some interference with the wing fit drift pins with some of the supporting sheet aluminum around the spar carry through bars. After doing some research I found that this is a common problem as the parts can shift a bit during riveting.

The fix is to very carefully enlarge the supporting aluminum sheet with out touching the spar carry through bars. This took a long time but turned out very well. I used a dremel tool to do the adjusting and some wood dowels to protect the spar carry through.

Also:

- Finished left gusset after tweaking the spar carry through

- Primed both fuselage gussets

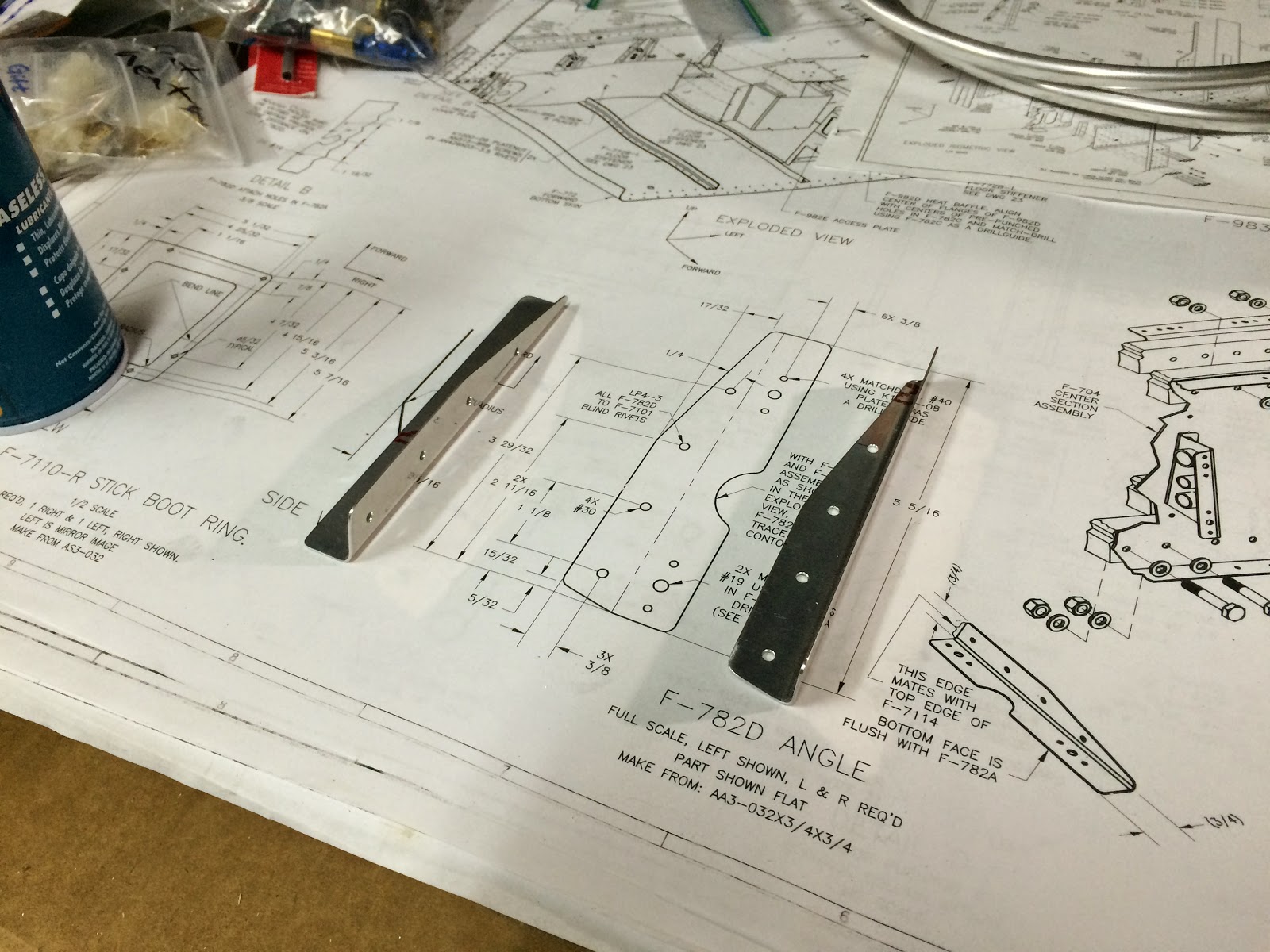

- Did some grinding and polishing of the seat floor rib connector pieces to allow full control travel (also primed these pieces)

- Very carefully drilled and deburred two additional holes for wiring in the spar carry through structure

Fine tuning gusset and spar carry through fit:

Opening up floor rib connectors to allow full control travel: