I got a lot of small tasks done today:

I worked on the panel mockup to lay out actual switch functions and added representations for lighting controls. There are a lot of switches (20+).

I tested my interior light led strips. The cockpit should be very well illuminated for night operations. The leds use very little power and have a very long life.

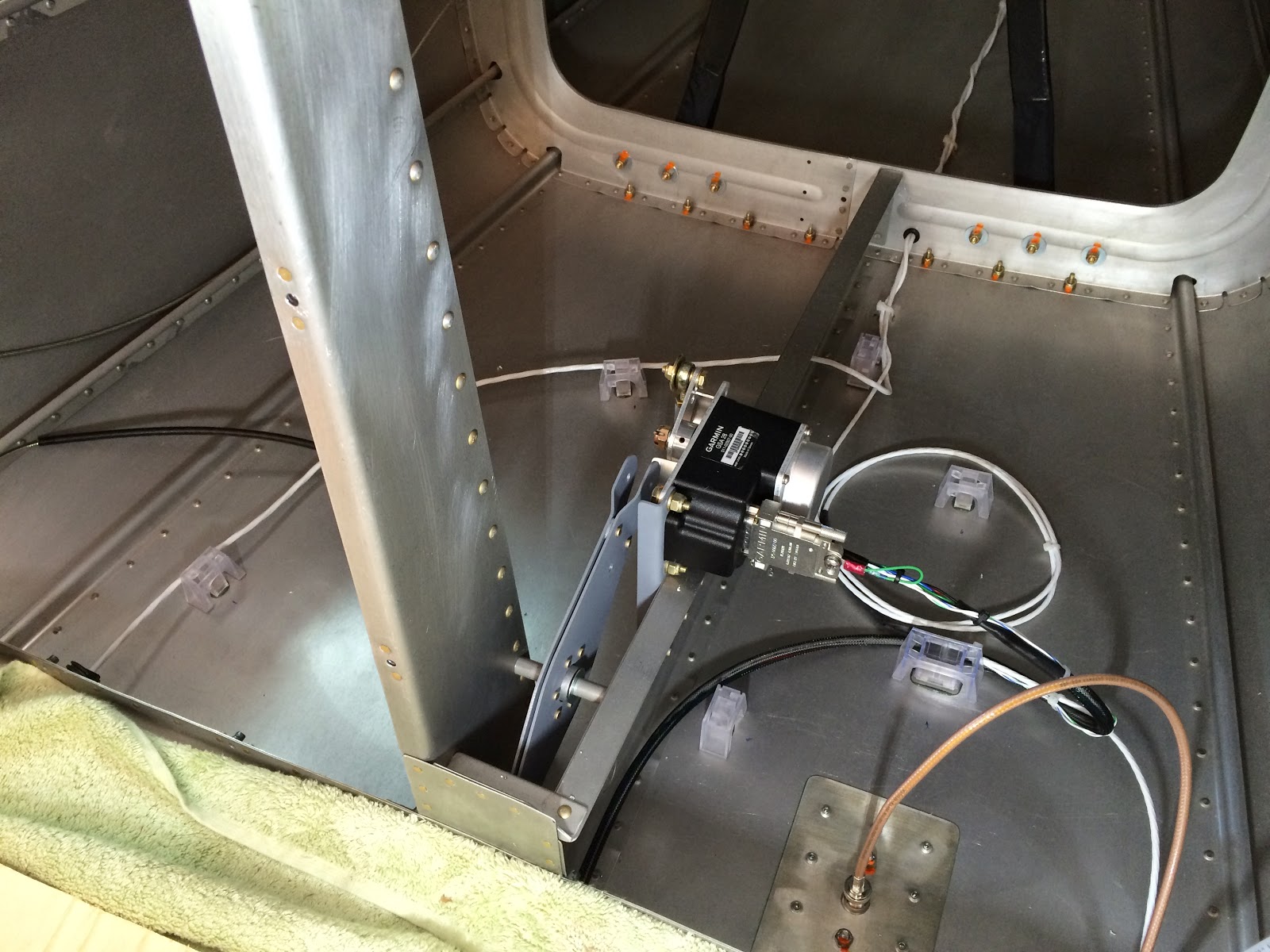

I ran the autopilot pitch servo wire bundle from the main spar back to the servo. I then assembled the servo dsub back shell connector. This wire harness was pre-made by Steinair but the individual pins still have to be inserted in the proper place in the connector. I also connected pitch trim servo to the cable for the auto pilot servo. In the Garmin system the pitch trim servo is controlled by the autopilot pitch servo.

I also ran the pitot static tubing, tail nav / strobe light wiring and adsb antenna cable through the fuselage conduit.

Finally I spent some time working out the best places to locate the led strips in the cockpit and how to run the wires.

Latest instrument panel mockup:

Putting pins in the ap pitch servo dsub connector:

Pitch servo connected:

LED light strip test: