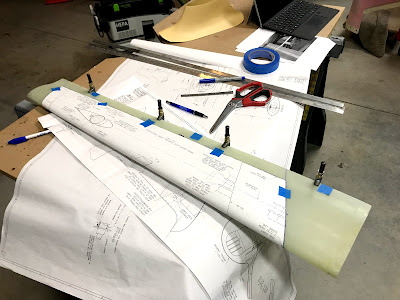

Once I trimmed the trailing edge of the gear leg fairings I put them on the landing gear and used the engine hoist (attached to the engine mount) and the tail lift to level the fuselage.

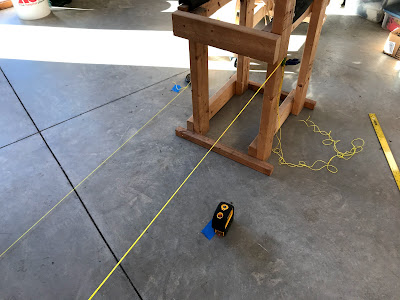

I used my very handy laser plumb bob to mark the fuselage center line on the floor. I then marked a reference point on the gear, made a parallel mark on the floor and put a string around the fairing. With that in place I could move the fairing to line it up with the aircraft center line.

The laser plumb bob made the whole process fairly easy: