The following is a big post with all the baffle work I have done since March. The baffles combined with the front cowling are a huge amount of work!

Here is the snorkel after the initial fiberglassing to reconnect the two pieces. This should be enough to lock it in position. When I get back from work I will remove it, reinforce it, and do the finishing including painting.

After prepping the pieces I used electrical tape as a rough form to lay the wetted out fiberglass strips on.

Trimming the lower piece for a slightly smoother transition.

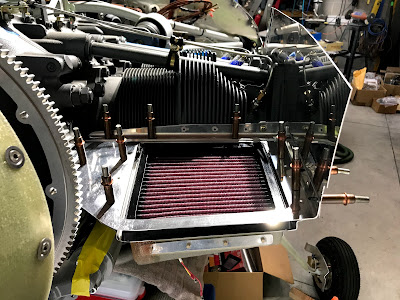

Getting the filter opening trimmed just right took a while. I also had to trim the left lower cowl nostril to clear the air filter. I will be making a removable hold down piece for the left and right side of the filter.

My fancy cnc machined o-ring valve covers have a slightly different profile from the stock ones so the baffles need to be trimmed a bit more....

A lot of baffles on / lower cowl on and off to get the fit dialed in.

The right conical gusset was really a hassle. The third try turned out good.

I used paper patterns, research on VAF and several attempts to work out the gusset.

To get the snorkel opening to work I cut it into three pieces then riveted the aluminum brackets to it. In this photo I’m getting ready to glass it back together.

Playing with snorkel alignment. The baffles, induction system and cowl are like a big jigsaw puzzle.

Snorkel after drilling, squaring off and sanding the front face level around the bolts.

Locating the holes precisely for the snorkel was involved but that’s normal for all of these parts. I used a stubby drill bit through the back side of the fuel servo to mark the holes.

Vans has you removing the prop oil line to take the baffles on and off. I think that is a bad plan so I came up with this mod. It was inspired by similar mods from the internet.

I used two number 8 screws, nut plates and a cover plate that allow the oil line to stay in place.

Just getting started on fitting the left baffle ramp with the cowl:

Drilled the 4” hose flange to the rear left baffle wall (after cutting the 4” hole!):

I also spent some time finish sanding my patched cowl bulge. It’s turning out good. I don’t think it will be visible at all after primer.