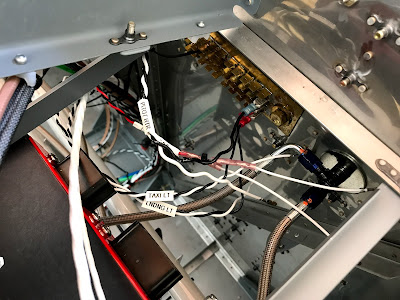

- Mounted pins in VPX connectors - wires will need to be organized more once all are in place

- Soldered leads on panel switches for: starter arm, push to start and auto level

- Ran servo wire for oil cooler servo

- Ran power wire for servo controller on panel

- Ran wire for engine starter switches to panel and out of firewall

- Installed fire sleeve for right firewall pass through

- Ran power from VPX to panel fuel pump switch

Slightly more organized:

Still a lot of pins to fill on the aft facing side:

Fireproof pass through:

Auto level button soldered:

Start switches soldered: