The following items were done over several days-

- Finished painting firewall doublers and battery boxes

- Opened up all holes on forward top skin for cherry max rivets

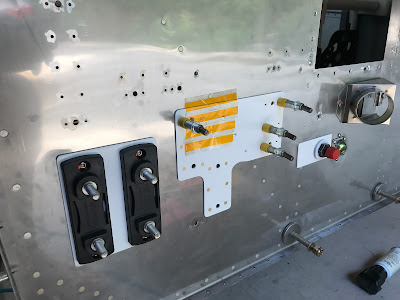

- I decided to add a anl fuse for the main VPX power feed so I made another doubler and drilled it to the firewall. I also made a copper bus bar to connect it.

- I started riveting the doublers to the firewall. I started with the fuse holder doubler for the alternators.

- I removed the forward top skin and support structure. I also located where I will mount the manifold pressure sensors for the electronic ignition.

Finishing up the painting:

Forward top skin drilled:

Locating the fuse holder for the main power feed:

Drilling main power feed doubler:

Checking fit with bus bar:

Alternator fuse holder doubler riveted on:

Locating manifold pressure sensor mounting location: